Ultra-Fast Mold Protection Sensor in High-Speed Pressing: Function, Benefits, and the Need for Implementation

In high-speed pressing processes, every millisecond counts. Even the slightest interruption or error can lead to serious damage to molds, equipment, or even a complete production line shutdown. In this context, the use of ultra-fast mold protection sensors—especially optical curtain sensors—plays a critical role in enhancing safety, preserving equipment integrity, and optimizing productivity.

Sensor Functionality

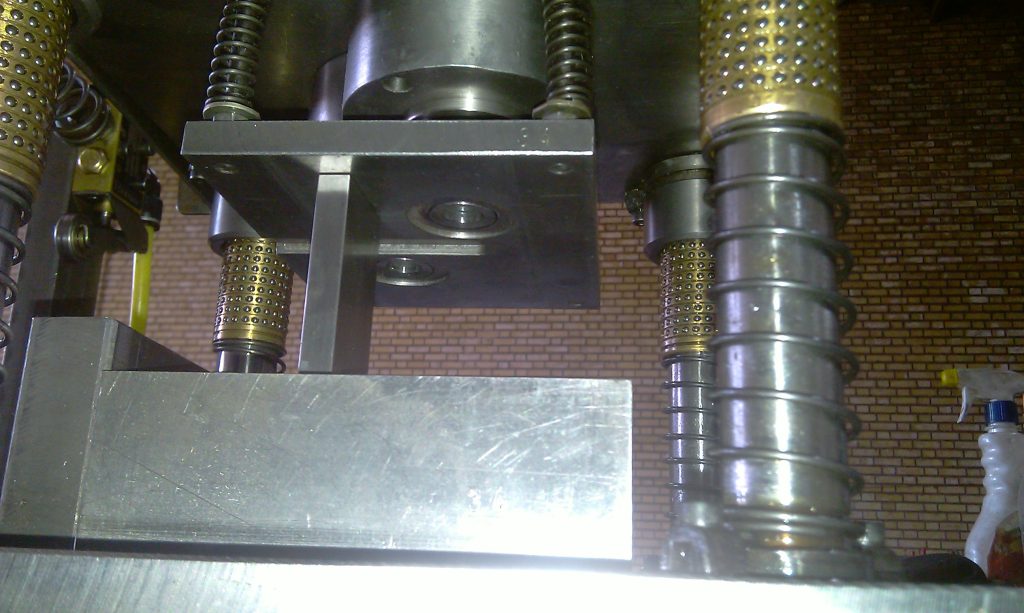

These sensors are typically high-response light curtain sensors. They are usually installed at the part ejection point from the mold, so that when the part is ejected by air pressure, it passes in front of the sensor and triggers a detection signal.

If the part fails to pass in front of the sensor after the previous operation, the press machine automatically stops or enters a hold mode. This feature prevents potential damage to the mold from unintended impacts and also ensures operator safety.

Advantages of Using Ultra-Fast Light Curtain Sensors

-

Prevention of Mold Damage: Ensures the part has exited before the next stroke, preventing impact on the part or mold.

-

Increased Mold and Equipment Lifespan: Prevents unwanted pressure and reduces overall wear and tear.

-

Reduction in Emergency Downtime: The sensor’s fast and automatic response helps avoid unexpected production halts.

-

Improved Production Speed and Safety: Greater reliability in part ejection allows for higher press speeds without risk.

-

Adjustable and Easily Integrated with Control Systems: These sensors can be seamlessly integrated with PLCs and press machine controllers.

Why Is Using a Die Protection Sensor Essential?

In mass and industrial production, even a single unintended press stroke can lead to mold failure, part deformation, and production line stoppage. This risk is significantly higher in high-speed dies. The ultra-fast die protection sensor acts as a smart technology to minimize this risk and plays a key role in preventive maintenance as well.

Conclusion

Leading companies in the field of industrial equipment engineering and manufacturing—such as Honico—by utilizing advanced die protection sensors, have not only enhanced the safety and efficiency of production lines but also significantly reduced equipment wear, maintenance costs, and unexpected downtimes.